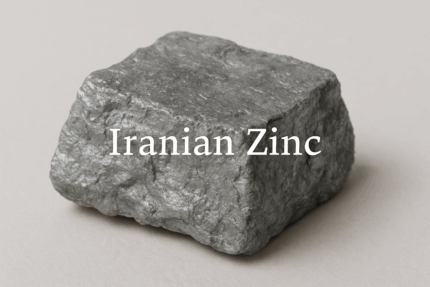

Iron ore

Iron ore, as one of the fundamental raw materials in global steel industries, plays a vital role in developing industrial and infrastructure projects.

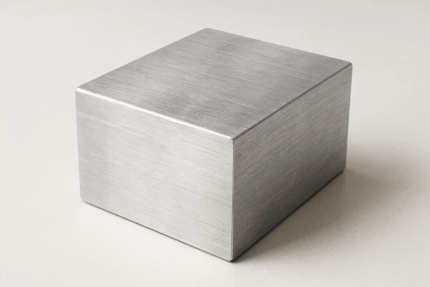

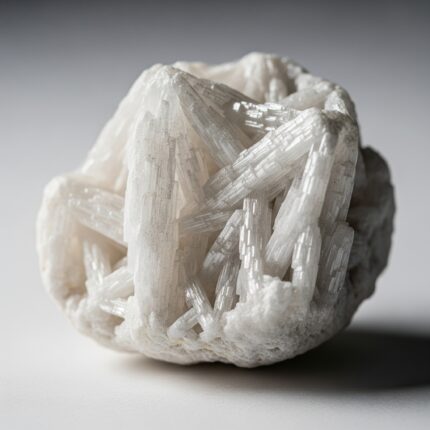

Iron ore, as one of the fundamental raw materials in global steel industries, plays a vital role in developing industrial and infrastructure projects. Iran, with vast iron‑ore reserves exceeding 2.7 billion tonnes in provinces like Kerman, Yazd, and South Khorasan, ranks among the top ten countries possessing this valuable mineral. Iranian iron ore is mainly extracted in the forms of hematite, magnetite, and goethite, each with an iron‑content purity between 55–70%, produced and processed according to international standards ISO 3082 and ASTM E877. High product quality, driven by advanced crushing, separation, and enrichment technologies in Iran’s mining complexes, enables competitiveness with Australian and Brazilian counterparts.

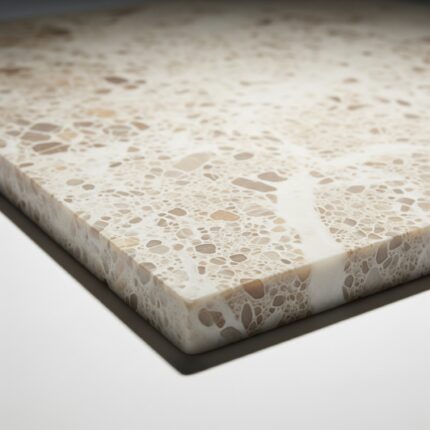

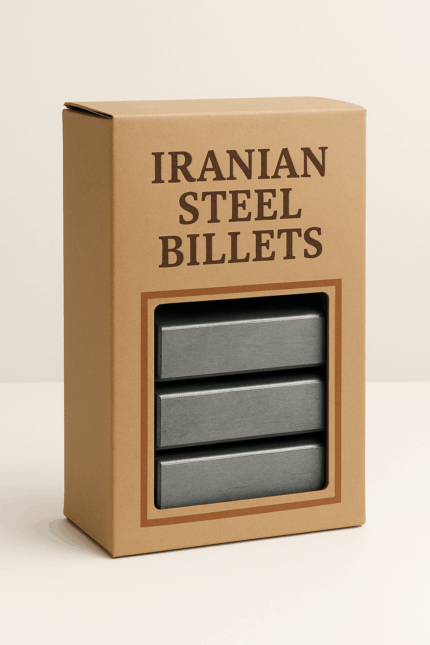

Iranian iron ore is offered in two primary forms: concentrate (67–69% Fe) and pellets (65–67% Fe), both used in steel production, automotive manufacturing, and heavy equipment industries. The main advantages over foreign examples are competitive pricing—thanks to lower extraction costs—easy access to southern ports (especially Bandar Abbas), and flexibility in supplying customized volumes. Modern processing factories like Chadormalu Mining & Industrial Company and Sangan allow production of iron ore with impurities under 2% silica, reducing energy consumption in blast furnaces by up to 15%.

Iranian Iron Ore: Driving Global Steel Industries

With the steel industry needing over 2.3 billion tonnes of iron ore annually, Iran produces 55 million tonnes per year, making it the third-largest producer in the Middle East and a strategic exporter to neighboring and distant markets.

Technical Features and Types

Key grades:

-

Hematite (Fe₂O₃): 65–70% Fe, red-gray, mostly used for stainless steel.

-

Magnetite (Fe₃O₄): 60–68% Fe, strongly magnetic, ideal for direct reduction furnaces.

-

Goethite (FeO(OH)): 55–62% Fe, mainly for pig iron production.

Iranian concentrates come in granules of 0–10 mm with moisture ≤ 8%, while pellets boast compressive strength over 250 kg/cm², enhancing performance in blast furnaces.

Export Markets

China remains the largest importer of Iran’s iron ore, accounting for over 60% of total exports. The Chinese market favors Iranian ore due to its relatively high quality and prices that are typically 10–15% lower than comparable Australian products, making it a cost-effective alternative for steel manufacturers.

The UAE and Oman also import significant volumes of Iranian iron ore, driven by ongoing large-scale infrastructure and urban development projects. Their proximity to Iran allows for efficient maritime transport, ensuring steady and timely deliveries.

Turkey benefits from well-established and efficient rail links with Iran, enabling cost-effective overland transport. Its demand for Iranian ore is fueled by a growing domestic steel industry and favorable logistics compared to more distant suppliers.

Russia and Kazakhstan, increasingly isolated by Western sanctions, have strengthened trade ties with Iran. Both countries view Iranian iron ore as a viable and accessible resource to support their industrial sectors while avoiding Western-controlled supply chains.

Iran’s strategic geographic position and expanding regional partnerships further boost its export potential, reducing shipping times and costs for nearby markets. Ongoing trade agreements and regional cooperation initiatives are expected to support sustained growth in iron ore exports.

Competitive Advantages

-

Rich reserves: Fourth-largest in Asia with 2.7 billion tonnes.

-

Advanced infrastructure: 12 processing complexes with annual capacity over 40 million tonnes.

-

Product range: Lump, concentrate, and pellet options.

-

Low logistics costs: Mines are within 500 km of southern ports.

New Market Development Strategy

Targeting rising infrastructure demand in Africa (Nigeria, South Africa) and India, Iran Store, in partnership with Iranian traders, plans to participate in major trade fairs like METEC (Germany) and EXPO METALURGIA (Spain) to showcase production capabilities and expand global distribution networks.

Technological Innovations in Processing

New HYL III plants in Kerman province produce 67%‑grade pellets with sulfur content under 0.01%, positioning Iran as a key supplier of low-impurity iron ore for advanced steelmaking.

Final Word: Golden Opportunity with Iran Store

Iran Store, as the gateway for Iranian iron‑ore exporters to global markets, offers comprehensive services: current pricing, trade documentation (Certificate of Origin, lab analysis), and logistics consultancy. To request samples, learn about special shipping terms, or negotiate long‑term contracts, contact Iran Store today.

Quality Guarantee: All export consignments include SGS certificates and undergo pre‑shipment inspections.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.