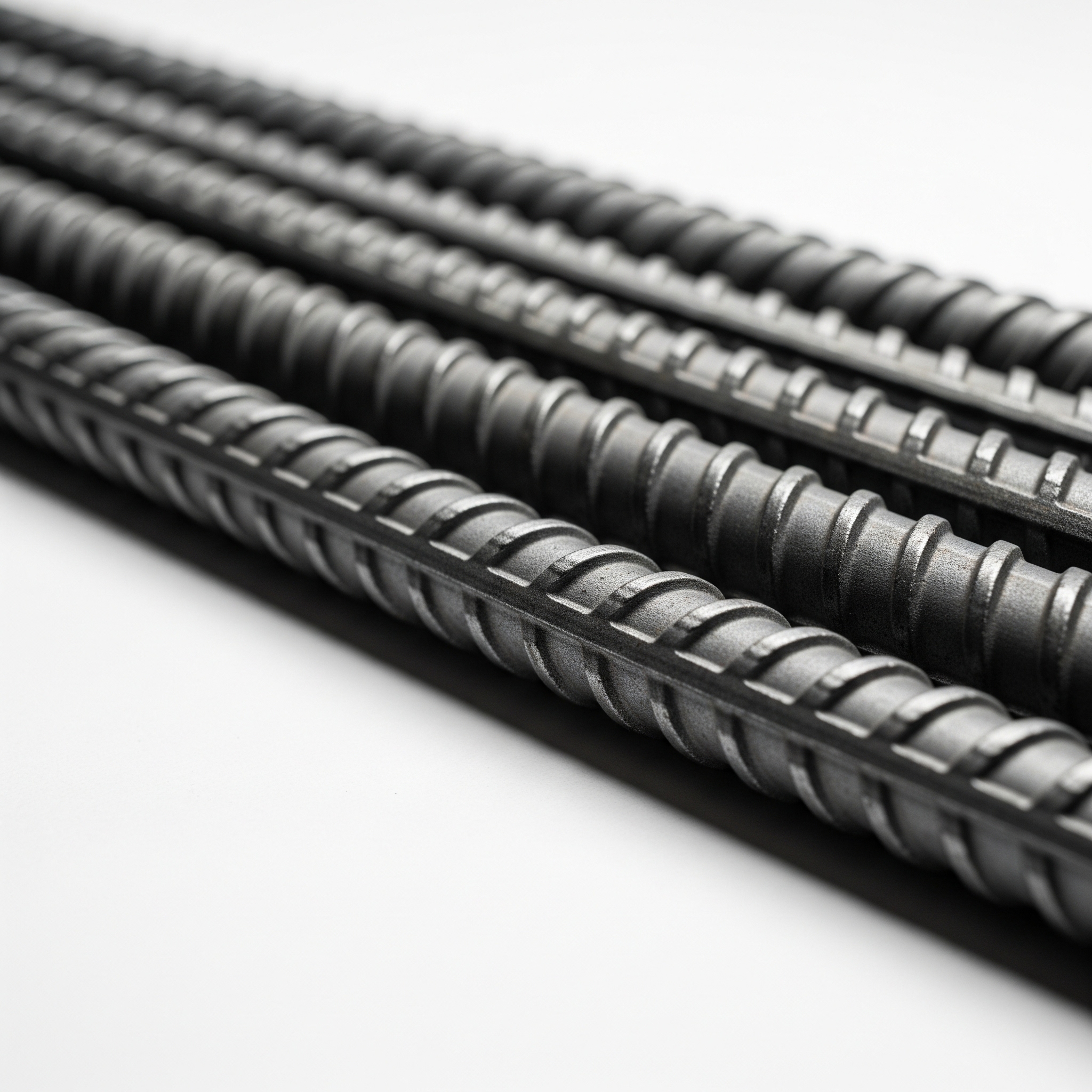

Iranian Rebar

Iranian rebar is one of the most essential construction materials, playing a vital role in civil projects, structural frameworks, and structural reinforcement worldwide.

Iranian rebar is one of the most essential construction materials, playing a vital role in civil projects, structural frameworks, and structural reinforcement worldwide. Manufactured in advanced Iranian facilities, this product complies with international standards such as ASTM A615, DIN 488, and ISO 6935. It is available in various types including plain rebar, deformed rebar (with spiral, herringbone, and compound ribs), epoxy-coated rebar, and stainless steel rebar. Iranian rebars are highly regarded in global markets due to their high tensile strength (around 500 to 600 MPa), excellent bonding with concrete, and flexibility during bending.

With access to rich iron ore reserves and state-of-the-art hot and cold rolling technologies, Iran has succeeded in producing rebar with quality comparable to Turkish, Chinese, and Russian products. Unique features of this product include corrosion resistance in epoxy-coated rebars for humid regions, resistance to dynamic stresses during earthquakes, and a service life of over 50 years in structures. Thanks to direct access to raw materials and affordable energy, Iranian rebar is priced up to 25% lower than European alternatives, making Iran one of the top 10 rebar exporters worldwide.

The main export markets for Iranian rebar include Iraq, the UAE, Afghanistan, Oman, Turkey, India, and Kazakhstan, with over 1.5 million tons of Iranian rebar imported annually for highway, mega-bridge, and residential complex projects. Iranian rebars are offered in various packaging forms (2-ton bundles, 500 kg coils, and 6 to 12-meter rods) and come with ISO 9001, IMIQ, and CE certifications.

Types of Iranian Rebar and Technical Features

Iranian rebars are categorized by application and production process as follows:

-

Deformed Rebar: The most widely used type in reinforced concrete structures, with surface ribs that enhance concrete bonding by up to 40%. Common grades include A1 (mild), A2 (semi-hard), and A3 (hard).

-

Epoxy-Coated Rebar: Its epoxy layer protects against moisture, salt, and chemicals, making it ideal for coastal structures like piers and marine bridges.

-

Stainless Steel Rebar: Composed of 16% chromium and 8% nickel, it offers exceptional corrosion resistance and is widely used in the pharmaceutical and food industries.

-

Galvanized Rebar: With a zinc coating, it ensures durability in industrial zones with high air pollution.

Standards and Technical Specifications

-

Diameter: Ranges from 8 mm to 40 mm (most demanded export sizes: 10, 14, and 16 mm).

-

Standard Length: 6, 9, and 12-meter rods with a ±50 mm length tolerance.

-

Yield Strength: 400 MPa for grade A3 and 500 MPa for grade A4.

-

Certifications: All products come with a Mill Test Certificate (MTC), Certificate of Origin, and Chemical Analysis Report.

Key Export Markets

Iraq: Due to post-war reconstruction projects, Iraq imports over 600,000 tons of Iranian rebar annually. Geographic proximity and competitive pricing have brought Iran’s market share in Iraq to 45%.

United Arab Emirates: Use of Iranian epoxy rebar in Dubai’s artificial islands and luxury towers has led to a 30% growth in exports to the UAE over the past two years.

Afghanistan & Oman: Demand for A2-grade rebars in low-rise construction presents a golden opportunity for exporting semi-hard Iranian products.

India & Kazakhstan: These countries’ focus on railway and bridge infrastructure has increased the demand for 32 to 40 mm diameter rebars.

Competitive Advantages of Iranian Rebar

-

Competitive Pricing: Thanks to low production costs and customs exemptions in some countries, Iranian rebar is up to 25% cheaper than rivals.

-

Diverse Coatings & Sizes: Ability to supply stainless, epoxy-coated, and galvanized rebars in custom sizes.

-

Logistics Infrastructure: Combined land-sea transport via Bandar Abbas and Bandar Anzali enables fast delivery to target markets.

-

Technical Support: Engineering consultation provided for selecting the appropriate grade based on soil type, climate, and structural design.

Applications in Various Industries

-

Building Construction: Used in foundations, columns, concrete slabs, and shear walls to improve earthquake resistance.

-

Bridge Construction: High-diameter rebars (32–40 mm) are used for bridge foundations and tension cables.

-

Oil & Gas Industry: Stainless and epoxy rebars are used in offshore platforms and pipelines.

-

Industrial Equipment: Applied in storage racks, heavy machinery, and machine parts.

Final Word:

Combining world-class quality, exceptional pricing, and compliance with global standards, Iranian rebar is the best choice for importers. Iran Store, as the official representative of leading steel factories, is ready to provide technical consultation, price quotes, and supply of various types of rebar in custom volumes. For premium-quality rebar and the best offer, contact our experts through our website or fill out the inquiry form now.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.